Solar eclipse on April 8 dazzles sky watchers across Quebec An eclipse is a phenomenal astronomical event. The total solar eclipse on April 8 was beyond expectations,…

Two NASA astronauts completed the second in a pair of spacewalks today (Feb. 1), installing a European science platform and finishing up a long series of battery replacements outside the International Space Station.

Today’s spacewalk, which began at 7:56 a.m. EST (1256 GMT), was the 234th spacewalk, or extravehicular activity (EVA), in support of space station assembly, maintenance and upgrades, according to NASA. The 233rd spacewalk took place just a few days prior, on Jan. 27.

This spacewalk was conducted by NASA astronaut Victor Glover and NASA astronaut Mike Hopkins. This marked Glover’s second spacewalk and Hopkin’s fourth spacewalk.

“Enjoying the view,” Hopkins said about the view of the Earth from space during the spacewalk.

Related: The International Space Station: inside and out (infographic)

Glover and Hopkins had a variety of tasks to tackle when they stepped out into space. After completing their main objectives — which included configuring a battery and adapter plate and installing three separate cameras — just about four hours into what was planned to be a six-and-a-half-hour spacewalk, the astronauts were able to complete some “get-ahead” activities.

“We went out the door a little bit late today but we’ve made up all that time,” Hopkins said during the spacewalk.

The pair was assisted by personnel including NASA astronaut Kate Rubins and Japan Aerospace Exploration Agency (JAXA) astronaut Soichi Noguchi on board the space station and NASA astronaut Bob Hines, who relayed next steps to the spacewalkers from the ground.

Throughout the duration of the mission, Glover used the “call sign,” or nickname, of “Ike, Hopkins used the name “Hopper” and Hines went by “Farmer.”

First, after leaving the space station airlock, Glover and Hopkins installed the final lithium-ion battery and adapter plate on the port 4 (P4) truss. The adapter plate completed the circuit for the battery system. This was the last in a series of battery-installment EVA activities that began in January 2017 to replace old nickel-hydrogen batteries with new lithium-ion batteries. Hopkins installed a scoop, a handling aid, on the lithium-ion battery to help with the installation.

“Final adapter plate installed on the @Space_Station. Today’s spacewalk will wrap up battery replacement work to change out batteries for 8 power channels used to route electricity on the station. Upgrades have been carried out in a series of spacewalks over the past 4 years,” NASA tweeted about the accomplishment.

✅ Final adapter plate installed on the @Space_Station. Today’s spacewalk will wrap up battery replacement work to change out batteries for 8 power channels used to route electricity on the station. Upgrades have been carried out in a series of spacewalks over the past 4 years. pic.twitter.com/Gmg7TmPA0sFebruary 1, 2021

“1 hr into today’s spacewalk and we have confirmation that the final Li-ion battery installed has a good configuration. @AstroVicGlover and @Astro_Illini are continuing to work on their tasks on the station,” NASA confirmed in another tweet.

The astronauts then drilled one bolt to secure the Direct Current Switching Unit (DCSU), which helps to route power through the station’s battery system.

Following the completion of this main task, Hopkins worked to remove the H-fixture, a grapple fixture bracket on the same truss as the battery that were once used for ground processing of solar arrays and are not needed any longer. Hopkins loosened and removed four bolts using a tool on a retractable tether. These fixtures are necessary for future power upgrades, NASA commentator Leah Cheshier noted during the agency’s broadcast.

Glover next began replacing a magenta-hued camera on the starboard truss; the camera’s color wheel had broken. To do this, Glover had to ride the station’s robotic arm, Canadarm2, over to the area. The arm, which provides added stability during the maneuver, was robotically controlled by Rubins from the space station.

To get onto the arm to “ride” it to the site, Glover had to attach and configure an articulating, portable foot restraint that would connect his feet to the arm. Before the maneuver, Hopkins did a quick helmet absorption pad (HAP) check to make sure nothing was leaking inside the suit.

Once secure on the arm, and with help from Rubins inside the orbiting laboratory, Glover “flew” over to the camera’s site, with the blue hues of the Atlantic Ocean swirling hazily below. Glover successfully replaced the broken camera on the starboard truss, the first of three cameras to be installed during the spacewalk. To do this, Glover used a pistol grip tool (PGT), which astronauts use to remove and install bolts during spacewalks.

Next, as the crew flew into orbital nighttime, Hopkins and Glover moved to work on two other camera systems on the space station. The pair worked to install a new HD camera on the U.S. Destiny laboratory module and then Hopkins worked to replace pieces of the camera system on the remote manipulator system on the Japanese robotic arm.

Glover then moved to exit the foot restraint on Canadarm2, jokingly saying, “I’d fly with ‘Air Rubins’ anytime,” as astronaut Rubins commanded the arm as he rode it.

At this point, just about four hours into the spacewalk, the astronauts had completed all major tasks set out for the event and moved on to “get ahead” tasks, or extra objectives that would otherwise be done during a later spacewalk.

During this final stretch of the spacewalk, Hopkins removed an additional H-fixture and took photos of the space station’s exterior to document its current state. Glover prepared the foot restraint configuration (that he earlier used for the robotic arm ride) for a future spacewalk. Glover also removed and replaced an airlock magnet, a metal plate that helps to keep the thermal cover on the space station’s Quest Joint Airlock closed.

Five hours and 20 minutes after they began, at 1:16 p.m. EST (1816 GMT), the astronauts began repressurizing the airlock and the spacewalk was officially over.

“Just want to say thank you to the entire … Farmer and vincent and everybody else, well done … i think we had a very very very good day … Thanks to everyone,” Hopkins said as the spacewalk ended.

Following today’s spacewalk, the Expedition 64 astronauts will conduct two additional spacewalks in the near future, according to NASA. Next, Glover and Rubins will prepare the space station’s power system for the installation of new solar arrays and, in the spacewalk after that, Rubins and Noguchi will continue to upgrade space station components, according to NASA. The exact dates for those spacewalks have not yet been set.

Today’s spacewalk coincides with the first day of Black History Month. Glover, who completed today’s spacewalk with Hopkins, is the first Black astronaut to take part in a long-duration mission on the station, staying for over six months as part of Expedition 64 and Expedition 65. Glover, who launched to the space station on Nov. 15, 2020, as part of SpaceX’s Crew-1 mission, is only the 15th Black astronaut to ever reach space.

“It is something to be celebrated once we accomplish it, and, you know, I am honored to be in this position and to be a part of this great and experienced crew,” Glover said during a 2020 news conference before he launched to the space station. “And I look forward to getting up there and doing my best to make sure that, you know, we are worthy of all the work that’s been put into setting us up for this mission.”

This spacewalk also coincides with the anniversary of the loss of STS-107, the Space Shuttle Columbia mission that, on Feb. 1, 2003, ended in tragedy the shuttle broke up while returning to Earth, killing all seven astronauts on board: Rick Husband, Michael Anderson, David Brown, Kalpana Chawla, Laurel Clark, William McCool and Ilan Ramon. The crew had successfully made it to space, where they spent 16 days and performed about 80 experiments before attempting to return to Earth.

An investigation determined that during launch, a large piece of foam fell from the shuttle’s external tank and hit the spacecraft’s wing. That damage caused the shuttle’s reentry failure. This tragic event moved NASA to take a hard look at their safety protocols and internal workplace culture to prioritize future astronaut safety.

Email Chelsea Gohd at cgohd@space.com or follow her on Twitter @chelsea_gohd. Follow us on Twitter @Spacedotcom and on Facebook.

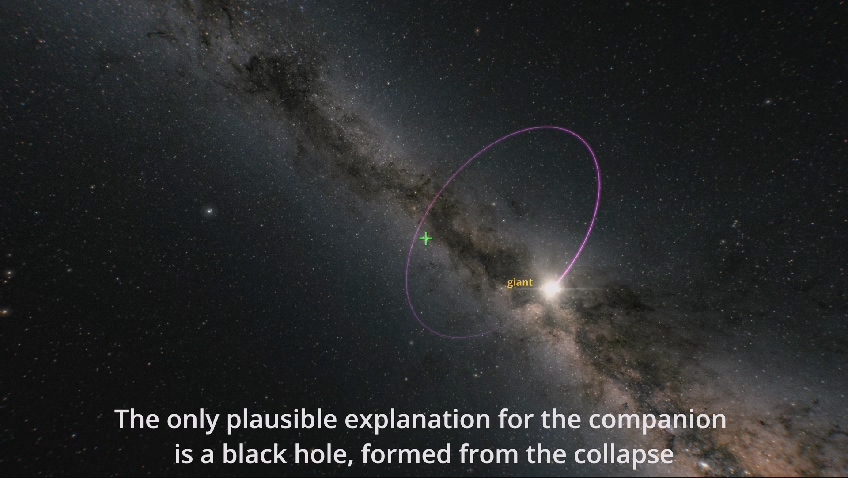

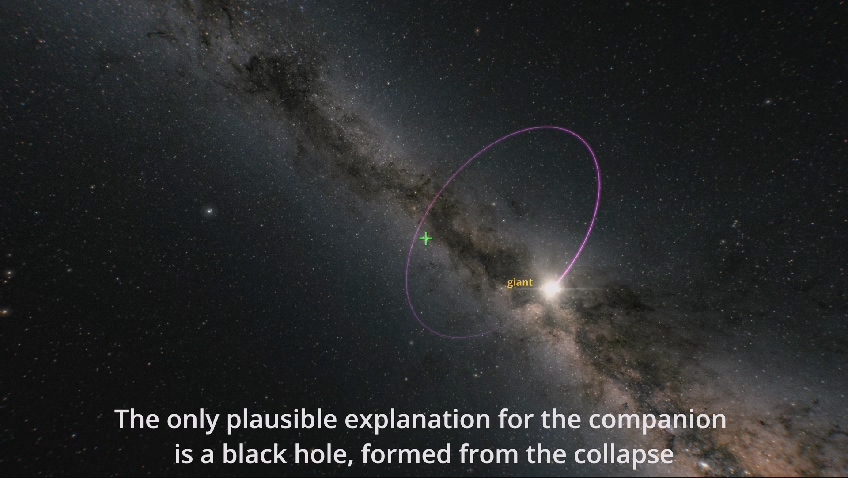

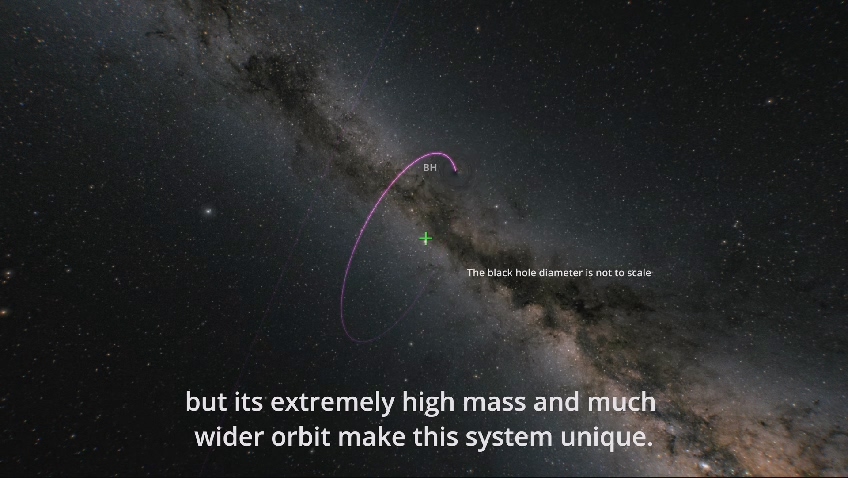

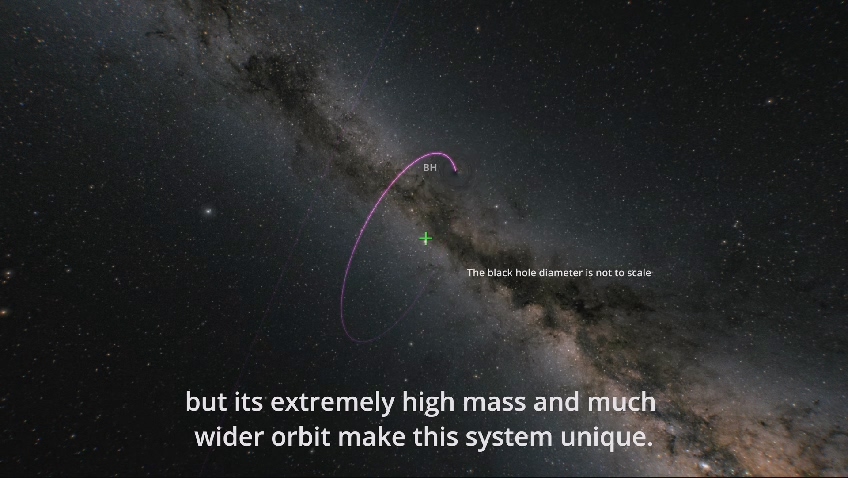

JERUSALEM, April 16 (Xinhua) — Astronomers have found BH3 is by far the heaviest known stellar black hole in the Milky Way galaxy, 33 times the mass of the Sun.

An international research team found the black hole when looking into the latest data group recorded in the European Space Agency’s Gaia space telescope, Israel’s Tel Aviv University (TAU) said in a statement on Tuesday.

The black hole is located 1,500 light-years away from Earth, said TAU, whose researchers participated in the study of the newly discovered binary system.

In binary systems, a visible star can be found orbiting a massive but unseen companion, indicating the latter is a black hole.

Binaries have revealed around 50 suspected or confirmed stellar-mass black holes in the Milky Way, but scientists think there may be as many as 100 million in our galaxy alone, according to NASA.

Stellar-mass black holes are formed when a star runs out of its nuclear combustion fuel and collapses.

The massive black hole BH3 was detailed in the open-access journal Astronomy & Astrophysics for further study.

“It almost hit my son” – three years ago the International Space Station threw out refuse into space, expecting it to undergo “a natural re-entry”.

But a heavy piece of debris crashed through a home in Naples, Florida, narrowly missing the householder’s son.

Team Canada’s Olympics looks designed by Lululemon

Search platform ranks Moncton real estate high | CTV News – CTV News Atlantic

Motorola's Edge 50 Phone Line Has Moto AI, 125-Watt Charging – CNET

Space exploration: A luxury or a necessity? – Phys.org

Political interference in Canada’s pension funds is wrong

RECAP: Red Wings' 5-4 comeback OT victory against Canadiens the result of belief, resiliency | Detroit Red Wings – NHL.com

Former mayor appealing sexual assault conviction dies of cancer

Firefighters battle wildfire near Edson, Alta., after natural gas line rupture – CBC.ca