Despite best efforts, we’re still decades if not generations away from regularly living and working off-planet — whether that’s in LEO habitation rings, moon bases, or on the Martian surface. Until humans can colonize space ourselves, we must rely on robotic orbitals, landers and rovers to physically interact with the galaxy around us. As Lucy Condakchian, General Manager of Robotics at Maxar, noted to an assembled audience at TechCrunch Sessions on Tuesday, actually touching the stars is still no easy feat.

Science

The company behind the robotic arms that help us explore Mars – Engadget

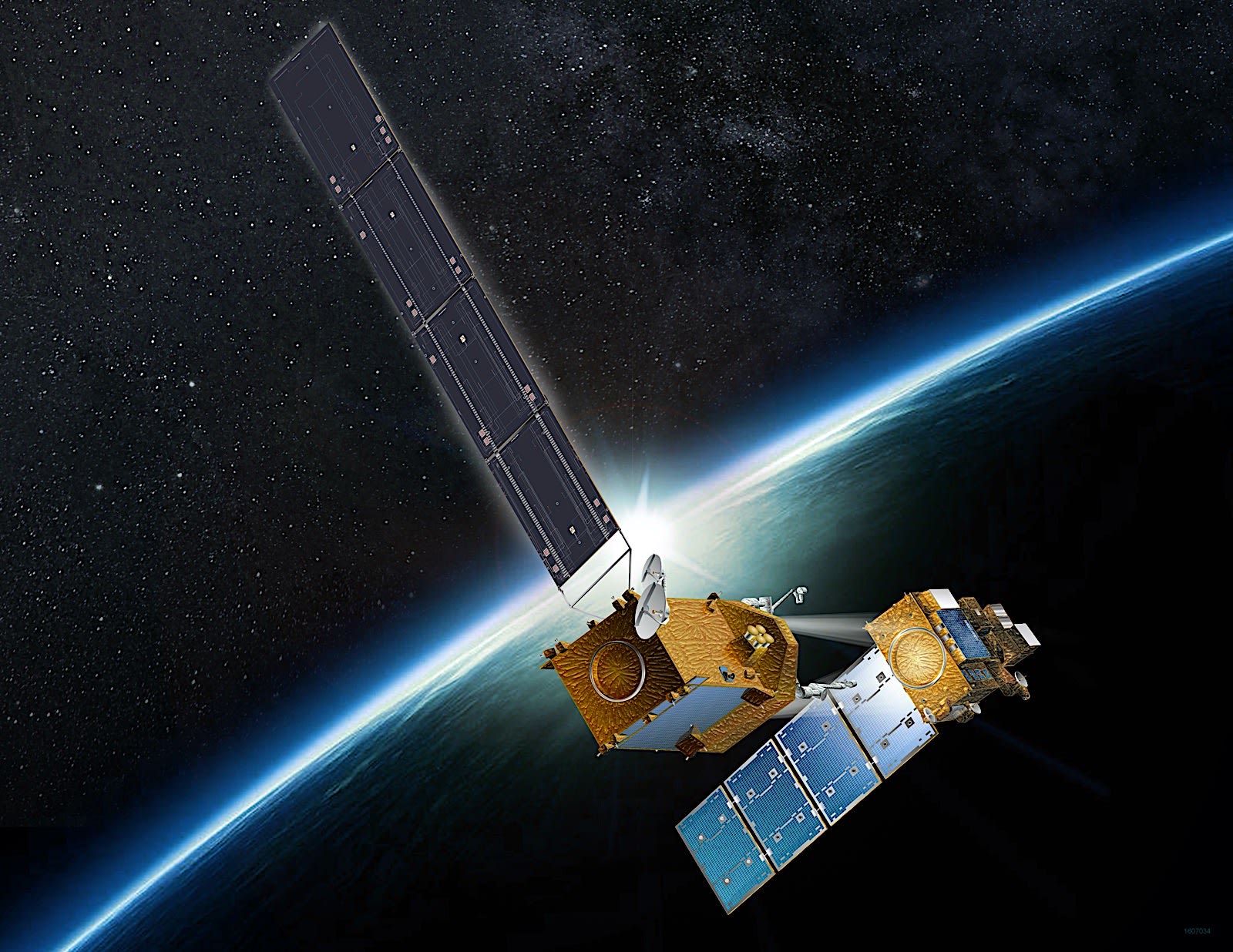

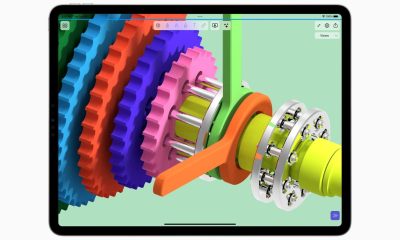

Maxar Technologies knows a thing or two about building space-based systems. The company has been developing and deploying satellite technology since 1969. It’s built robotic arms for NASA since the Apollo era, as well as for commercial customers — over 75 in total. In fact, all five robotic arms currently on the surface of Mars were built by Maxar.

“I would absolutely call it a collaborative partnership,” Condakchian told Engadget. “Over the years as NASA has changed, what their pursuits are, what our administration has asked them to do, we just bend in flux.”

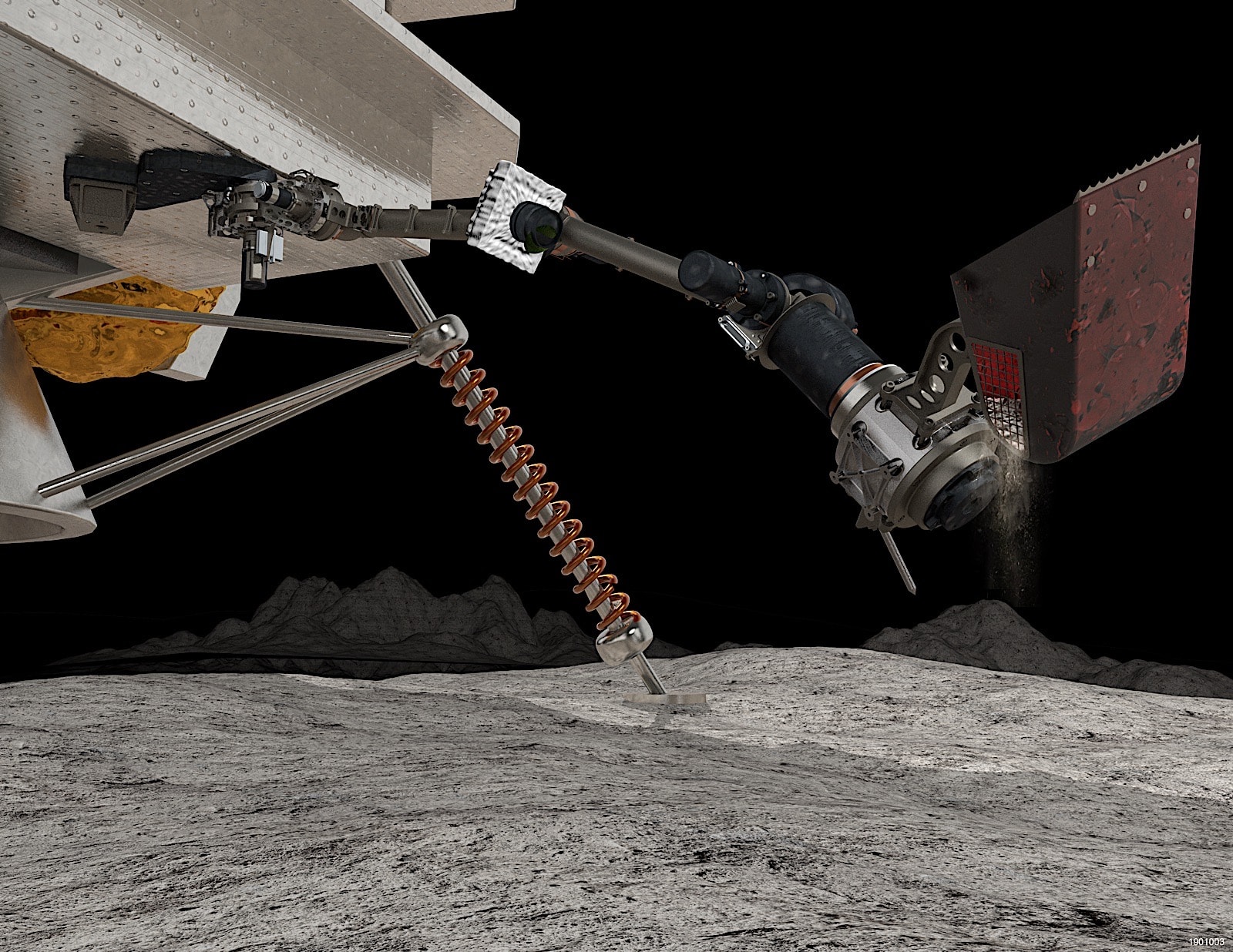

The company’s sixth Mars-bound arm, dubbed the Sample Handling Assembly (SHA), will be aboard the Mars 2020 Rover. This mission is part of NASA’s larger Mars Exploration Program and is scheduled to launch in July.

Once safely upon the Red Planet, the SHA will drill into the Martian dirt to collect soil and rock core samples from the most interesting sources it can find, then squirrel them away in a secure cache on the planet’s surface. The hope is that a future mission might be able to collect the samples and return them to Earth for study.

“You build on the heritage,” Condakchian told the Sessions audience, pointing out that the first arm to arrive on the Martian surface was barely a meter long with “five degrees of freedom and five joints that actually moved.” But over the course of numerous iterations, the latest arm boasts double that length with seven joints and seven degrees of freedom.

The company is also working on a sampler arm — conveniently named the Sample Acquisition, Morphology Filtering and Probing of Lunar Regolith or SAMPLR — as part of the 2024 Artemis mission to the moon. The $5 million piece of space hardware will be the first robotic arm deployed to the moon in 50 years, where it will sift through layers of dust to determine “the geotechnical properties of lunar regolith.”

SPIDER will be integrated with the spacecraft bus Maxar is building for @NASA Restore-L project, which will refuel a satellite in low Earth orbit. SPIDER will enable spacecraft components to be robotically assembled and reconfigured while on-orbit. Learn more: pic.twitter.com/XfPquzmsKi

— Maxar Technologies (@Maxar) January 31, 2020

Maxar is even looking beyond planetary surfaces and is currently developing arms for use in orbit to service and repair aging satellites, such as the SPIDER for NASA’s Restore-L program. However that environment provides its own unique set of challenges compared to planetside operation.

On Earth, “you know where you’re going to set that robotic arm, you know what [conditions] you’ll encounter… and you also can go and service it,” Condakchian said. “Our robotic arms, once they’re in space, we’re done. If it’s mission critical, it cannot fail. It has to survive.” And in space, she continued, “You’ve got radiation to deal with. You’ve got temperature swings, you’ve got materials that you cannot use.”

As such, each arm is largely built to the specific mission requirements, though some overlap between individual mission designs does occur. “We don’t want to reinvent the wheel every single time, right?” Condakchian explained. “There’s definitely elements of it that we build on and we’ve learned that this kind of actuator design works well for this type of application gives you this type of output, etc… Most of our government customers actually want a lot more tailored solutions.”

Recent advances in 3D printing are helping tailor those solutions more easily and with a greater degree of precision than conventional subtractive manufacturing techniques. Condakchian points out that issues of around machining components to the exacting tolerances that modern spacecraft require are negated with 3D-printed pieces. What’s more, “some parts are going to actually be lighter because your load paths within the components of that robotic arm,” she said. “You don’t need to think about how to machine this off of a block of aluminum or titanium.”

Improvements in AI systems are also improving the performance of these arms, providing them a greater degree of autonomy. However, that expanded capability must be carefully balanced against the massive investment required. “It’s a balance of adding that new capability and technology without impacting the integrity or increasing the risk of the mission,” Condakchian told the Sessions audience.

Currently NASA retains human-in-the-loop oversight, wherein if the rover detects an anomaly in the environment or its actions, it can enter a Safe Mode and phone back to mission control for clarification and further instruction. Problem is that it takes a signal 13 minutes to make it from Mars to Earth plus another 13 minutes back plus however much time it takes the NASA boffins to determine the best course of action. It’s a slow process but still better than wrecking a multimillion dollar piece of equipment because the onboard AI flummoxed itself.

Maxar is also looking into wireless energy transmission as a potential weight saving measure. “Trying to send energy down the whole robotic arm to get video feedback, that’s extra mass and that’s extra power draw,” Condakchian said. “That’s a limiting factor.”

And though only two of the five robotic arms on Mars are currently operational, Condakchian explained, the inoperable ones from the Spirit and Opportunity rovers as well as the Phoenix lander are actually rugged enough to be brought back online and put back to work if we were somehow able to clear the Martian dust that has caked their solar panels. If only they had an extra arm equipped with a squeegee.

Science

Giant prehistoric salmon had tusk-like teeth for defence, building nests: study – CP24

Brenna Owen, The Canadian Press

Published Wednesday, April 24, 2024 7:27PM EDT

Last Updated Wednesday, April 24, 2024 7:27PM EDT

The artwork and publicity materials showcasing a giant salmon that lived five million years ago were ready to go to promote a new exhibit, when the discovery of two fossilized skulls immediately changed what researchers knew about the fish.

Initial fossil discoveries of the 2.7-metre-long salmon in Oregon in the 1970s were incomplete and had led researchers to mistakenly suggest the fish had fang-like teeth.

It was dubbed the “sabre-toothed salmon” and became a kind of mascot for the Museum of Natural and Cultural History at the University of Oregon, says researcher Edward Davis.

But then came discovery of two skulls in 2014.

Davis, a member of the team that found the skulls, says it wasn’t until they got back to the lab that he realized the significance of the discovery that has led to the renaming of the fish in a new, peer-reviewed study.

“There were these two skulls staring at me with sideways teeth,” says Davis, an associate professor in the department of earth sciences at the university.

In that position, the tusk-like teeth could not have been used for biting, he says.

“That was definitely a surprising moment,” says Davis, who serves as director of the Condon Fossil Collection at the university’s Museum of Natural and Cultural History.

“I realized that all of the artwork and all of the publicity materials and bumper stickers and buttons and T-shirts we had just made two months prior, for the new exhibit, were all out of date,” he says with a laugh.

Davis is co-author of the new study in the journal PLOS One, which renames the giant fish the “spike-toothed salmon.”

It says the salmon used the tusk-like spikes for building nests to spawn, and as defence mechanisms against predators and other salmon.

The salmon lived about five million years ago at a time when Earth was transitioning from warmer to relatively cooler conditions, Davis says.

It’s hard to know exactly why the relatives of today’s sockeye went extinct, but Davis says the cooler conditions would have affected the productivity of the Pacific Ocean and the amount of rain feeding rivers that served as their spawning areas.

Another co-author, Brian Sidlauskas, says a fish the size of the spike-toothed salmon must have been targeted by predators such as killer whales or sharks.

“I like to think … it’s almost like a sledgehammer, these salmon swinging their head back and forth in order to fend off things that might want to feast on them,” he says.

Sidlauskas says analysis by the lead author of the paper, Kerin Claeson, found both male and female salmon had the “multi-functional” spike-tooth feature.

“That’s part of our reason for hypothesizing that this tooth is multi-functional … It could easily be for digging out nests,” he says.

“Think about how big the (nest) would have to be for an animal of this size, and then carving it out in what’s probably pretty shallow water; and so having an extra digging tool attached to your head could be really useful.”

Sidlauskas says the giant salmon help researchers understand the boundaries of what’s possible with the evolution of salmon, but they also capture the human imagination and a sense of wonder about what’s possible on Earth.

“I think it helps us value a little more what we do still have, or I hope that it does. That animal is no longer with us, but it is a product of the same biosphere that sustains us.”

This report by The Canadian Press was first published April 24, 2024.

Science

Nasa's Hubble marks 34th anniversary with stunning view of Little Dumbbell Nebula – The Times of India

In celebration of its 34th anniversary, Nasa‘s Hubble Space Telescope has once again wowed astronomers and space enthusiasts alike by capturing an extraordinary image of the Little Dumbbell Nebula. This latest image offers a vivid glimpse into the complexities of a planetary nebula, demonstrating Hubble’s enduring capabilities in its extended mission.

The Little Dumbbell Nebula, also known as Messier 76, is one of the faintest objects in the Messier catalog and has intrigued astronomers for its intricate structure and dual-lobed shape. This planetary nebula, located approximately 2,500 light-years away in the constellation Perseus, represents a brief stage in the life cycle of a moderate-sized star like our sun.

Dr. Jennifer Wiseman, a senior scientist at Nasa’s Goddard Space Flight Center, expressed her admiration for the new imagery: “This beautiful nebula is what remains after a star like our own sun has exhausted the bulk of its nuclear fuel and shed its outer layers. The vibrant colors and intricate structures visible in the nebula are a telescope’s way of painting the portrait of the final stages of stellar evolution.”

The Little Dumbbell Nebula, despite its faintness, shines brightly in the detailed images provided by Hubble, allowing scientists to study aspects of the nebula that are rarely visible. The images highlight the dense, glowing gas and complex layers of material expelled from the dying star at the center of the nebula.

According to Dr. Wiseman, “Hubble’s high-resolution capabilities allow us to examine the fine details within the nebula, helping us understand how stars expel their material and the dynamics of this expulsion process. This image is more than just a picture; it’s a deep dive into the life of stars.”

Since its launch on April 24, 1990, Hubble has revolutionized our understanding of the universe, from the dynamics of galaxies to the atmospheres of exoplanets and the distribution of dark matter. Its contributions continue to support and complement data gathered by newer space observatories.

As Hubble continues its journey in space, the scientific community remains enthusiastic about the ongoing contributions it will bring to our understanding of the cosmos. Dr. Wiseman remarked, “Every image from Hubble is a new lesson in our cosmic curriculum.”

These observations not only contribute significantly to our knowledge of the life cycle of stars but also continue to highlight the critical role of Hubble in the exploration and understanding of our universe. As Hubble enters another year in orbit, its legacy of discoveries promises to keep inspiring both the scientific community and the public.

Science

SpaceX launch marks 300th successful booster landing – Phys.org

SpaceX sent up the 30th launch from the Space Coast for the year on the evening of April 23, a mission that also featured the company’s 300th successful booster recovery.

A Falcon 9 rocket carrying 23 of SpaceX’s Starlink internet satellites blasted off at 6:17 p.m. Eastern time from Cape Canaveral Space Force Station’s Space Launch Complex 40.

The first-stage booster set a milestone of the 300th time a Falcon 9 or Falcon Heavy booster made a successful recovery landing, and the 270th time SpaceX has reflown a booster.

This particular booster made its ninth trip to space, a resume that includes one human spaceflight, Crew-6. It made its latest recovery landing downrange on the droneship Just Read the Instructions in the Atlantic Ocean.

The company’s first successful booster recovery came in December 2015, and it has not had a failed booster landing since February 2021.

The current record holder for flights flew 11 days ago making its 20th trip off the launch pad.

SpaceX has been responsible for all but two of the launches this year from either Kennedy Space Center or Cape Canaveral with United Launch Alliance having launched the other two.

SpaceX could knock out more launches before the end of the month, putting the Space Coast on pace to hit more than 90 by the end of the year, but the rate of launches by SpaceX is also set to pick up for the remainder of the year with some turnaround times at the Cape’s SLC-40 coming in less than three days.

That could amp up frequency so the Space Coast could surpass 100 launches before the end of the year, with the majority coming from SpaceX. It hosted 72 launches in 2023.

More launches from ULA are on tap as well, though, including the May 6 launch atop an Atlas V rocket of the Boeing CST-100 Starliner with a pair of NASA astronauts to the International Space Station.

ULA is also preparing for the second launch ever of its new Vulcan Centaur rocket, which recently received its second Blue Origin BE-4 engine and is just waiting on the payload, Sierra Space’s Dream Chaser spacecraft, to make its way to the Space Coast.

Blue Origin has its own rocket it wants to launch this year as well, with New Glenn making its debut as early as September, according to SLD 45’s range manifest.

2024 Orlando Sentinel. Distributed by Tribune Content Agency, LLC.

Citation:

SpaceX launch marks 300th successful booster landing (2024, April 24)

retrieved 24 April 2024

from https://phys.org/news/2024-04-spacex-300th-successful-booster.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

-

Science24 hours ago

Science24 hours agoNASA Celebrates As 1977’s Voyager 1 Phones Home At Last

-

Politics23 hours ago

Politics23 hours agoPecker’s Trump Trial Testimony Is a Lesson in Power Politics

-

Media23 hours ago

B.C. puts online harms bill on hold after agreement with social media companies

-

Media17 hours ago

B.C. online harms bill on hold after deal with social media firms

-

Business23 hours ago

Oil Firms Doubtful Trans Mountain Pipeline Will Start Full Service by May 1st

-

Real eState18 hours ago

Montreal tenant forced to pay his landlord’s taxes offers advice to other renters

-

Politics17 hours ago

Politics17 hours agoPolitics Briefing: Younger demographics not swayed by federal budget benefits targeted at them, poll indicates

-

Media22 hours ago

Trump poised to clinch US$1.3-billion social media company stock award